Manifold Fabrication 1

Fabricating the B16-AE101 manifold.

To mate up the AE101 bodies to the B series engine, I decided to make a manifold using the stock mounting flange cut from a spare B16A2 intake manifold - B16A2 because the port does not narrow before the injector pocket and more suited to this job. The difference is only around 1-2mm, but it makes all the difference.

A collection of flanges after being media blasted - you

can see how excellent the finish is. The top flange is

waiting to be trimmed, and the bottom flange is from a D

series DOHC engine for no reason other than I blasted it

at the same time.

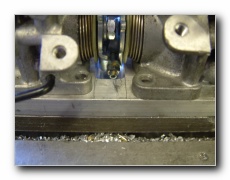

The flange has now been machined at an angle, and cleaned.

A flange for the AE101 bodies was cut from 12mm aluminium

plate, and machined to accept the bodies. I had to mill a

few slots to clear the throttle linkages. These were drilled

at 51mm to accept the 2" OD tubing I decided to use for the

runners.

The machined components ready to be test fitted.

The components were then test fitted with a spare head

to check for clearance against the firewall, and to work out

how much room I had spare for a intake horns filter/airbox.

The tubes have now been cut to the approximate length

and the flange has been drilled & tapped for the

throttle bodies. The air horns and filter can now be

ordered.

The tubes have also been finished with a flap wheel, the

whole setup is now ready for welding. The welding will be

performed by an engineering shop as I only have access to an

180amp TIG, which is too lightweight for the thick 12mm

flange.